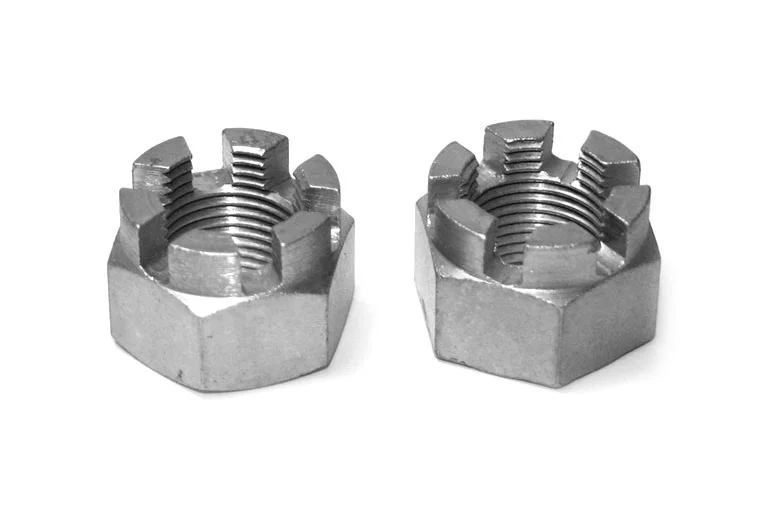

A castle nut, also known as a castellated nut, features three notches on one end, resembling the crenellated battlements of a castle. This design makes the castle nut a reliable locking mechanism, ensuring that it remains securely in place and resists vibrations.

How Castle Nuts Work

Castellated nut are typically used in conjunction with a screw that has a pre-drilled radial hole. When the castle nut is fastened, a pin is inserted through the notches and into the screw’s hole, preventing any movement of the nut. Various types of pins can be employed for this purpose, including:

- Cotter Pin: A fastener with two tines that are bent after insertion to secure it in place.

- R-Clip: Also known as a hairpin cotter pin, this spring-loaded fastener has one straight leg that goes into the hole and a curved leg that grips the outside of the nut.

- Safety Wire: To secure the castle nut, a wire is twisted and anchored after being passed through the screw hole and notches.

Applications of Castle Nuts

Castle nuts are utilized across various industries, serving both commercial and residential needs. In the automotive sector, Castellated nut play a crucial role in securing components like spark plug wires, alternators, starters, and drive shafts. They are also common in heavy machinery, such as tractors and snowplows, where they hold parts together firmly while allowing for easy maintenance access.

In residential settings, you can find Castellated nut in many household appliances with moving parts, including refrigerators, washing machines, stoves, and air conditioners. Their versatility and reliability make castle nuts an essential component in numerous applications.

Why Use a Castle Nut?

One of the primary advantages of using a castle nut is its enhanced security against loosening due to vibrations or external forces. Unlike traditional fasteners such as bolts, which often require drilling before installation, Castellated nut are quick and easy to install, saving both time and effort.

Additionally, Castellated nut are highly durable and resistant to corrosion, outperforming many other metal fasteners. Their design features slots instead of threads, which allows for even pressure distribution, further increasing their longevity and reliability.

Properties of Castle Nuts

- Design: Castle nuts, often referred to as slotted nuts, feature a slot cut into their side, facilitating secure fastening.

- Applications: They are commonly used in critical applications where preventing loosening is essential, such as in the automotive and aerospace industries.

- Materials: Typically made from robust materials like steel or brass, Castellated nut are built to withstand harsh conditions.

- Compatibility: The slot in a Castellated nut is specifically designed to align with a cotter pin, ensuring that the nut remains securely fastened.

- Variety: Castellated nut come in various sizes to suit different applications, making them versatile components in many settings.

Stainless Steel Metric Castle Nut Manufacturer in India

Ramesh Steel Corporation was established in 1983 by Mr. Ramesh D. Jain, a respected figure in the steel industry. With over 35 years of experience, Ramesh Steel Corporation specializes in manufacturing a wide range of steel fasteners, including Castellated nut, duplex steel fasteners, stainless steel fasteners, bolts, nuts, screws, and washers. Our clients span across countries such as Saudi Arabia, Kuwait, Turkey, the United Arab Emirates, Oman, Egypt, Indonesia, Malaysia, Singapore, Thailand, Sri Lanka, Russia, West Africa, and Latin America.

At Ramesh Steel Corporation, we are committed to quality and customer satisfaction. Our team of experienced engineers is dedicated to meeting complex and precisely defined requirements. We have successfully manufactured fasteners based on intricate drawings, where many companies have declined due to their complexity and the need for special grades.

Centrally located in Mumbai, India, Ramesh Steel Corporation has significantly contributed to the growth of duplex steel fasteners, stainless steel fasteners, castle nuts, bolts, and screws. We produce fasteners in various metals and grades, including Nickel 200/201, Monel 400/K500, Inconel 600, Inconel 625, Inconel 800, Inconel 825, Hastelloy C22/C276, Alloy 20, Titanium, and both duplex and super duplex materials.

Materials for Castellated nut

Castellated nut can be crafted from various materials, chosen based on specific application requirements such as strength, corrosion resistance, and environmental conditions. Common materials used for manufacturing castle nuts include:

- Steel: The most widely used material, offering a great balance of strength and cost-effectiveness. Low-carbon steel (Grade 2 or Grade 5) is suitable for general use, while high-carbon steel (Grade 8) provides enhanced strength. Stainless steel is ideal for corrosion-resistant applications.

- Brass: Often chosen for its corrosion resistance and aesthetic appeal, brass castle nuts are commonly used in marine and decorative applications.

- Aluminum: Lightweight and corrosion-resistant, aluminum castle nuts are popular in aerospace and aviation sectors, as well as in structures where reducing weight is essential.

- Bronze: Known for its strength and corrosion resistance, bronze castle nuts are frequently used in marine environments and applications involving high temperatures.

- Plastic: Castellated nuts composed of nylon or polyethylene can be used in non-critical applications. While lightweight and resistant to corrosion, they may not match the strength of metal Castellated nut.

Castle Nuts vs. Slotted Nuts

Castellated nut are often referred to as slotted nuts; however, there is a technical distinction. Castle nuts feature a rounded section at the top where the slots are located, while slotted nuts have flat sides that extend fully from top to bottom. The functionality and usability of castle nuts are improved by their distinctive design.

Castellated Nut Wrench: Essential Tool for Castle Nuts

A castle nut wrench, also known as a castellated nut wrench, is a specialized tool specifically designed for tightening or loosening Castellated nut. These fasteners feature slots or notches cut into one end, requiring a dedicated tool to engage effectively and apply the necessary torque.

Crucial Elements and Applications of a Castle Nut Wrench

- Design: Castle nut wrenches typically come in the form of box-end or socket wrenches, featuring a unique design that fits securely onto the notched end of the castle nut.

- Notch Engagement: The wrench is equipped with prongs or extensions that correspond to the pattern of the slots or notches in the Castellated nut. This design ensures a snug fit, preventing slippage while tightening or loosening the nut.

- Secure Grip: These wrenches provide a reliable grip on the slotted end of the Castellated nut, allowing for precise control and accurate torque application. This is particularly important in critical applications where proper torque is essential.

- Versatility: To suit varying castle nut dimensions, a range of sizes of castellan nut wrenches are provided. To guarantee a good fit and prevent nut damage, it is essential to choose the appropriate size.

Even though they might not be the most well-known fasteners, castella nuts are essential to many applications’ stability and safety. Their unique design allows for the insertion of cotter pins, adding an extra layer of security that is invaluable in safety-critical situations. Whether you’re working on automotive components, agricultural machinery, or structural engineering projects, the castle nut is a reliable and cost-effective choice for secure fastening.

Why Choose Castle Nuts?

- Security: The slots in Castellated nut enable the insertion of a cotter pin, creating a secondary locking mechanism. This double-locking system ensures that the nut remains firmly in place, even under extreme conditions.

- Easy Inspection: The visible slots in Castellated nut make it straightforward to check if the cotter pin is properly installed, simplifying maintenance and safety inspections.

- Cost-Effective: Castellated nut offer a budget-friendly solution for securing critical components. They are widely available and generally inexpensive.

- Versatility: Available in various sizes and materials, castle nuts can be utilized in a diverse range of applications.

Conclusion

In summary, castle nuts are essential fasteners that provide enhanced security and reliability in a variety of applications. Their unique design, featuring slots for cotter pins, ensures that they remain securely fastened even under extreme conditions. Utilizing a castle nut wrench allows for effective tightening and loosening, making it easier to maintain and inspect these critical components. With their cost-effectiveness and versatility, Castellated nut are a preferred choice across industries, from automotive to construction. Understanding their benefits and proper usage not only ensures safety but also contributes to the longevity of equipment and machinery. Whether you’re a professional or a DIY enthusiast, recognizing the importance of Castellated nut will help keep your projects secure and efficient.

FAQs about Castle Nuts

1. What is a castle nut?

A fastener with slots or notches carved into one end is called a castle nut. This design allows for the insertion of a cotter pin, providing a secondary locking mechanism that helps prevent loosening due to vibrations or external forces.

2. What is a castle nut used for?

Castellated nut are primarily used to secure components in various applications, ensuring they remain in place under challenging conditions. They are commonly found in automotive, aerospace, and heavy machinery settings, where safety and reliability are critical.

3. How do you install a castle nut?

To install a Castellated nut, first, thread it onto the corresponding bolt or screw. Once it is in place, align the slots with a pre-drilled hole in the bolt and insert a cotter pin or a locking wire to secure it. This prevents the nut from loosening.

4. What tools are needed to work with castle nuts?

To work with Castellated nut, you typically need a castle nut wrench, which is designed to fit the notched end of the nut. Additionally, standard hand tools like pliers may be needed to insert or remove cotter pins.

5. Can castle nuts be reused?

Castellated nuts can often be reused, but it is essential to inspect them for wear, deformation, or damage. If the nut shows signs of significant wear or if the cotter pin hole is enlarged, it’s advisable to replace it to ensure safety.

For getting More Information Thezvideo.